RECYCLABILITY

Much of packaging produced today cannot be recycled in existing recycling systems. This is especially true for multi-material packaging, which today poses a significant and unresolved challenge in recycling.

Obtaining a flexible recyclable packaging requires a combination of redesign and innovation in business models, materials, packaging design, and reprocessing technologies.

OUR RECYCLABLE PACKAGING SOLUTIONS

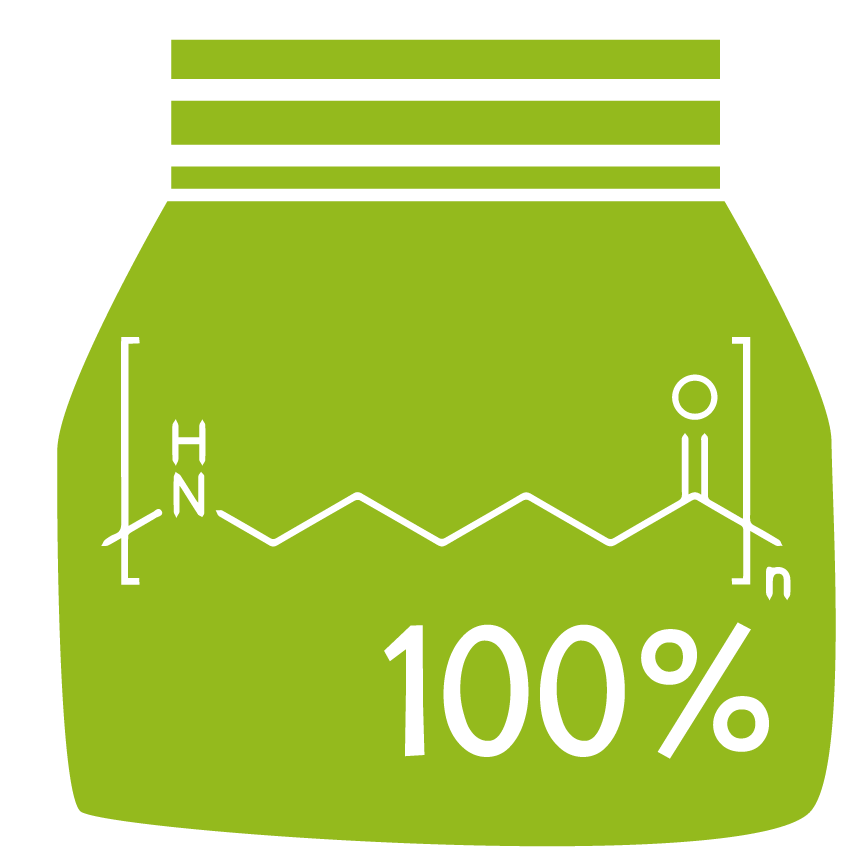

MONOMATERIAL POLYAMIDE

It can also be recycled pre-consumer, thus cutting industrial waste.

LDPE/PA RECYCLABLE STRUCTURE

Our up performing polyamide allows to loundage the PE laged up to 15% of the total PA plastic content thus allowing to recycled structures.

MONOMATERIAL POLYAMIDE PACKAGING

It is the perfect solution for those packages that require an oxygen barrier to extend the shelf life of food.

Our special copolyamide Promyde placed as a sealing layer over a full polyamide structure preserves the oxygen barrier, even in conditions of high ambient humidity, such as pasteurization and sterilization.

OTHER ADVANTAGES

High temperature resistant

Plastic reduction

Deep thermoforming

Sealable

Gloss and transparency

Double oxigen barrier

APPLICATIONS

Thermoformed tray

Vaccum bags

Barrier packaging

MULTILAYER DELAMINATION

Multimaterial barrier packaging has a complex recyclability. Now, thanks to INZEA, a water-soluble solution, is possible to delaminate the different layers of a barrier film for ulterior recycling.

INZEA dissolves in water at 60ºC and the flakes layers are separated during the water bath in the recycling process

OTHER ADVANTAGES

Oxigen barrier

APPLICATIONS

Food sachets applications

LDPE/PA RECYCLABLE STRUCTURE

Multimaterial PA-PE structures can now be recycled.

Thanks to the outstanding features of Promyde copolyamides, a thinner layer of PA will be sufficient to provide additional strength and barrier properties to your packaging.

If this polyamide layer represents less than 30% of the total weight of the packaging, this structure can be recycled into the PE stream.

OTHER ADVANTAGES

Oxigen barrier

Plastic reduction

APPLICATIONS

Trays and lids

Vaccum bags

Barrier packaging

WORKING TOGETHER TO MATCH YOUR SUSTAINABLE SOLUTION

Are you ready to turn your packaging into a sustainable solution?

CONTACT US

GET TO KNOW HOW OUR MATERIALS CAN HELP YOU TO REACH YOUR SUSTAINABLE GOALS FOR PACKAGING

If you want us to help you choosing the right material for your packaging, please fill-in your contact details and we will contact you back.

Headquarters & Production Plant

Address:

Ctra. Barcelona km 329 (N-IIa)

50016 Zaragoza (Spain)

See at Google Maps

Tel. +34 976 46 55 79 | Fax: +34 976 57 41 08

DISCOVER ALL OUR SUSTAINABLE PACKAGING SOLUTIONS

Achieving your sustainable goals is now possible by applying one or more of these strategies

PACKAGING SOLUTIONS

FOOD WASTE REDUCTION

PLASTIC REDUCTION

COMPOSTABILITY

BIODEGRADABILITY

BIOBASED

SUBSCRIBE TO OUR NEWSLETTER

RECEIVE NEWS FROM NUREL EVERY MONTH IN YOUR EMAIL: NEWS, JOB OFFERS OR INNOVATION AND SUSTAINABILITY ARTICLES

NUREL

Our history

SAMCA Group

BUSINESSES

Synthetic Fibers

Polymers

Biopolymers

SUSTAINABILITY

10 challenges

People

Environment

R&D

NEWSLETTER

News

Suscription

Contact

Contact us

Careers

LEGAL NOTICE

CAREERS

SAMCAnet

InfoSAMCA Channel

Corporate information

All information and material included on this website is not contractually binding – © NUREL, S.A. Any reproduction, of all or part of this website is expressly prohibited. NUREL, S.A. A-28171114 – Registro Mercantil de Barcelona Folio 12, Tomo 11544, Inscripción 90, Hoja nº B-55122.